If you have stumbled upon our website, chances are you are either an interior designer, a professional installer , DIY enthusiast, or a client looking to purchase microcement products for your builder.

The biggest confusion when it comes to microcement products is understanding the different systems and products available. With so many options available, it can be overwhelming to make the right decision. And if you are unsure about which product to buy and how many, don’t worry, you are not alone, we are here to help !

At ClaudiCemento, we believe in making your shopping experience easy and hassle-free. That’s why we have created this comprehensive guide to help you make the right choices for your project.

We understand that every project is unique and may require different products. That’s why we have a variety of microcement systems and products choose from. Our goal is to provide you with the best products and guidance to ensure your project is a success.

So, let ClaudiCemento be your go-to destination for all your microcement needs.

We guarantee high-quality products and excellent customer service. Start shopping now and let us help you bring your microcement project to life.

We offer Innovative ClaudiCemento READY MIX microcement – mineral, ready mixed mortar based on acrylic resins, additives and selected minerals to confer high mechanical and chemical performance with low VOC emissions. Ready to use, the material is intuitive to work with, making it simple for anyone to achieve the desired results.

ClaudiCemento READY MIX microcement is available in a wide range of colours and three distinct grain sizes: thick grain- BASE, medium grain- DECK, fine grain – FINE.

What should you consider before purchasing ClaudiCemento microcement products?

There are 5 elements that require attention:

- Substrate preparation,

- Product selection based on microcement installation area

- Your skillset

- Right number of products for your project

- Desired finish and colour.

We will take you through each of these elements to ensure that you have all the information you need to make the right decision.

You can also use our Product Recommendation Tool which will assist you in this process.

- Substrate preparation

To find out if your current substrate is suitable for the microcement installation please use our Substrate Preparation – Recommendation Table tool.

When installing microcement on a screed or concrete surface, the surface must meet certain requirements. These requirements include being level, clean, cured, dry, dust-free, and free of substances that could hinder adhesion. Microcement cannot be applied on non-solid substrate with any type of movement issues.

If the microcement is being installed on a new screed or concrete floor or plastered walls, it is important to ensure that the surface had enough time to cure and is free of moisture. It is common for freshly screeded floors to appear crack-free at first glance, but only after applying our bonding sealer/primer – No1 Sealer, will you be able to fully assess the condition of the subfloor.

Microcement can be applied to various surfaces such as tiles, glass, metal, screed, concrete, green MDF, and marine plywood. However, it should not be applied to wooden or laminated floors due to potential movement issues.

Before applying microcement, it is crucial to carefully inspect the subfloor for any cracks, moisture issues, unevenness, or movement issues. These issues must be addressed before installation begins.

All external areas must be water-tight and protected from wind, and roofs must also be water-tight. Prior to installation, any pipework and underfloor heating systems must be tested to ensure there is no water ingress, which can affect the curing process and final finish of the microcement.

Microcement should not be used as a levelling material as it is not time or cost effective. Instead, a load bearing self-levelling compound, screed, or our FIX ALL mortar system can be used.

When applying microcement on dry-lined walls, there are two options: plastering or taping and jointing. Plastering involves applying tape to joints and then coating the entire surface with plaster. Taping and jointing involve taping the joints and then applying three coats of jointing compound to the joints only.

When applying microcement to the walls with the cement boards on then either plastering or ClaudiCemento FIX ALL system should be used first as part of the substate preparation.

When applying microcement to the substrate with moisture issues such as damp, and/or in the basements , and /or in the outdoor areas then ClaudiCemento HYDRO FIX should be used first as part of the substate preparation.

When creating a furniture that is designed for a microcement coating, double up on moisture-resistant Green MDF, glue and screw it from the bottom, and flush and overlap the joints.

Proper attention must be paid to joints and movement during floor or wall preparation, as any future movement can result in cracks.

Under floor heating (UFH) should be turned off at least 3 days before application and can be turned back on after 28 days. Microcement cannot be applied directly on UFH pipes, as the substrate for microcement installation must be solid and load bearing.

Existing expansion joints should be mirrored, and any new ones should be designed by architects or structural engineers.

For more information about substrate preparation please go to our article ‘’ Rules of Successful microcement installation’ on our BLOG tab https://claudicemento.com/uncategorized/blog/rules-successful-microcement-installation/

- Product recommendation based on microcement installation area

| AREA OF INSTALLATION | CLAUDICEMENTO READY MIX |

|---|---|

| BATHROOMS AND WET ROOM WALLS AND FLOOR , FURNITURE , CEILINGS | BEST CHOICE |

OUTDOOR COMMERCIAL AND RESIDENTIAL AREA WALLS AND FLOOR ,FURNITURE | BEST CHOICE + HYDRO FIX |

| RESIDENTIAL FLOOR – LOW FOOT TRAFFIC | BEST CHOICE |

| RESIDENTIAL FLOOR – HIGH FOOT TRAFFIC | BEST CHOICE |

| INDOOR RESIDENTIAL WALLS , CEILINGS | BEST CHOICE |

| INDOOR COMMERCIAL WALLS | BEST CHOICE |

| INDOOR COMMERCIAL FLOOR | BEST CHOICE |

| FURNITURE INDOOR | BEST CHOICE |

| KITCHEN SPLASH BACK | BEST CHOICE |

| KITCHEN WORKTOP | BEST CHOICE |

| SWIMMING POOL | Not Suitable - enquire about MICRO-POOL |

3. Your skillset

ClaudiCemento offers a variety of products to suit different needs and skillsets. Whether you are a professional microcement installer or a DIY-er, there will be a suitable product for you in our offer.

If you are new to using microcement or have limited experience, we highly recommend going for ClaudiCemento READY MIX microcement. This product stands out as an innovative and superior choice, making it suitable for even first-time users. One of the key features that make ClaudiCemento READY MIX microcement ideal for all user levels is its simplified installation process. Unlike standard microcement, it does not require the use of a fiber mesh during installation. This not only saves time but also eliminates the added cost and hassle of acquiring and using a fiber mesh. Moreover, READY MIX microcement addresses a common issue with traditional microcement – drying too quickly under the trowel. This can make the installation process challenging and require a high level of workmanship. However, READY MIX product is specifically formulated to dry at a slower pace, making it much more user-friendly and easier to work with. This means that even those with limited experience can achieve professional-looking results.

In addition to its user-friendly installation process, ClaudiCemento READY MIX microcement also boasts impressive properties that make it stand out from traditional microcement. One of the most notable features is its waterproof properties. While standard microcement only becomes waterproof after sealing, ClaudiCemento READY MIX microcement has limited absorption and does not require a solvent-based sealer for protection. This not only saves additional time and effort but also makes it a more environmentally-friendly option. )

But thats not all that we can offer you ! There is even more support for you! ClaudiCemento offers excellent customer support and assistance to ensure a successful installation. We offer support and assistance before and during installation form our technical advice team, and for those who wish to enhance their skills we offer 2 days microcement workshops. So, if you are looking for a reliable microcement product that can cater to your specific skillset and needs, ClaudiCemento should be your go-to option!

4. Right number of products for your project – How much product do I need ?

When planning your microcement project, it is important to determine how much product you will need.

At ClaudiCemento, we understand that purchasing the right amount of product can be confusing. That’s why we have made it easier for you by offering KITs ranging from 10-100 sqm. Simply select the KIT that covers the area of your project and you are ready to go. Our KITs include all the necessary products for installing microcement, except for pigment. The pigment can be selected separately in the pigment tab. We have made the process as hassle-free as possible, so you can focus on creating a beautiful finished project with our high-quality microcement products.

It is crucial to make sure you have enough material for your project, as running out and having to redo the entire layer of microcement can end up costing you more in the long run. While our Kits come with a small material allowance, we recommend getting a larger one if you are not an experienced installer. This is especially important if you are applying the microcement on walls or ceilings. For example, if your project is 25 sqm, it is best to go for the 30 sqm KIT instead of the 20 sqm one.

If you need assistance in selecting the right product for projects over 100sqm, please contact us at order@claudicemento.com and our team will gladly assist you with any queries you may have.

The table below provides a helpful guide on product consumption when purchasing products separately.

Products Consumption table

| PRODUCTS | PACKEGING SIZE | COVERAGE (PER TWO COATS) |

|---|---|---|

| ClaudiCemento READY MIX DECK | 15kg | 16.5 SQM |

| ClaudiCemento READY MIX FINE | 15kg | 21 SQM |

| ClaudiCemento READY MIX BASE | 15kg | 10 SQM |

| No1 SEALER | 5L | 50 SQM |

| No1 Quartz SEALER | 5L | 50 SQM |

| PROTECTOR DUR MATT/SATIN | 5L + 1L | 50 SQM |

| FIBER MESH | 1M/10M or 1M/50M | 10 SQM or 50 SQM |

| FIX ALL | 25KG | 5MM THIKNESS - 8 SQM 8MM THIKNESS - 5 SQM |

| HYDRO FIX | 20 KG + 10 L | 19 SQM - PER ONE COAT |

| PIGMENTS | VARIES | READY MIX - ONE BOTTLE PER 15 KG BUCKET |

5. Desired finish

At ClaudiCemento we understand the importance of versatility and personalization. That’s why our microcement finishes cater to a variety of styles and preferences. Whether you’re looking for a strong and durable base layer, a stunning concrete-like appearance, or a subtle and refined finish, we have the perfect option for you.

Microcement Base:

ClaudiCemento microcement Base finish, characterized by its thick grain size. This durable and strong base layer forms the foundation of ClaudiCemento microcement systems – both traditional and READY MIX. While it is primarily used for its strength, some enthusiasts also appreciate its rustic appeal as a unique finishing layer, adding a touch of character to any space.

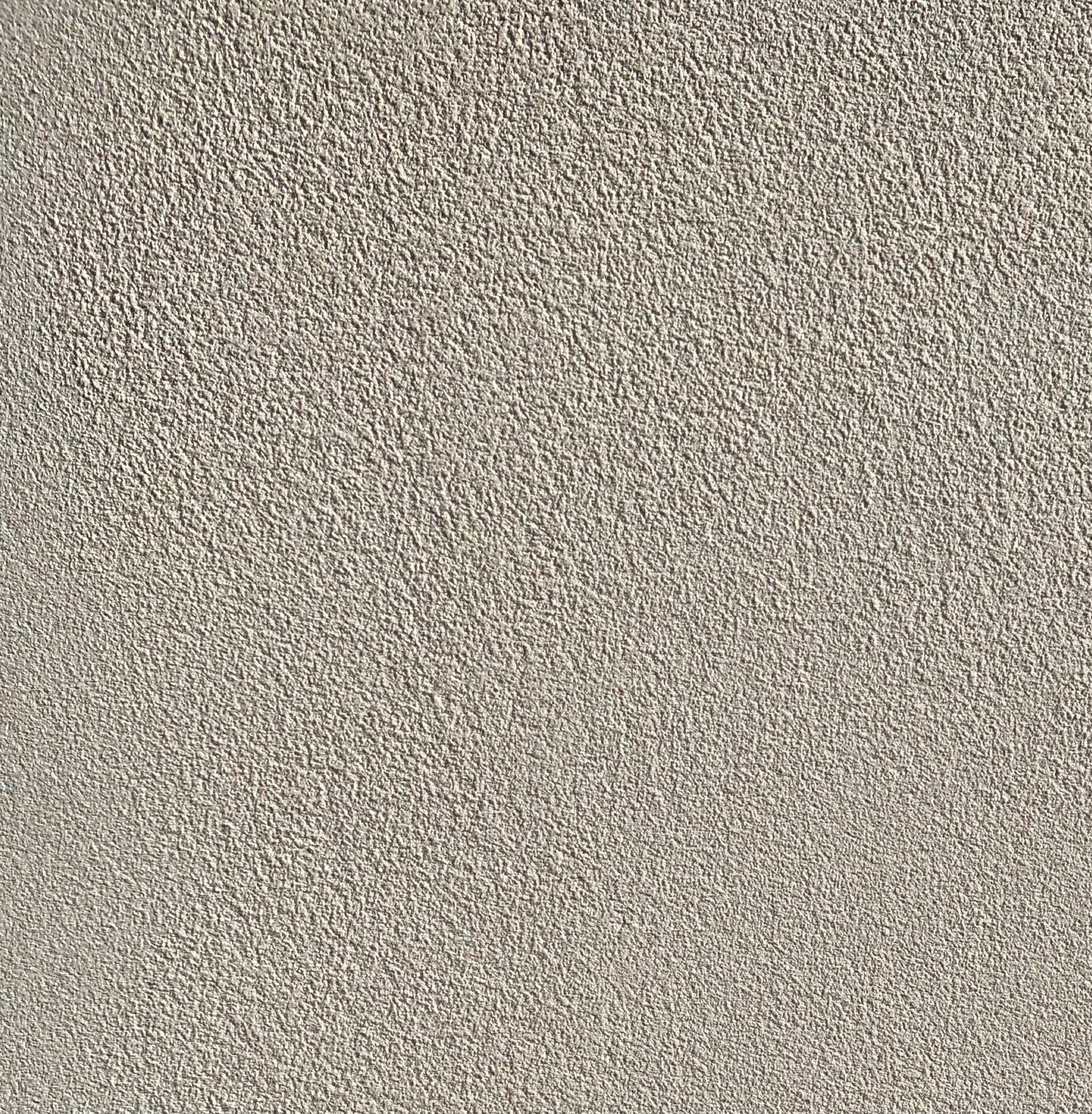

Microcement DECK

Next, we present the ClaudiCemento microcement Deck finish, designed to replicate the authentic look of concrete. With its medium-sized grain, it offers a mesmerising cloudy effect, complete with very attractive colour variations and a distinct concrete like pattern. It comes as no surprise that the Deck finish is highly sought after, as it effortlessly enhances any environment, creating a truly stunning result.

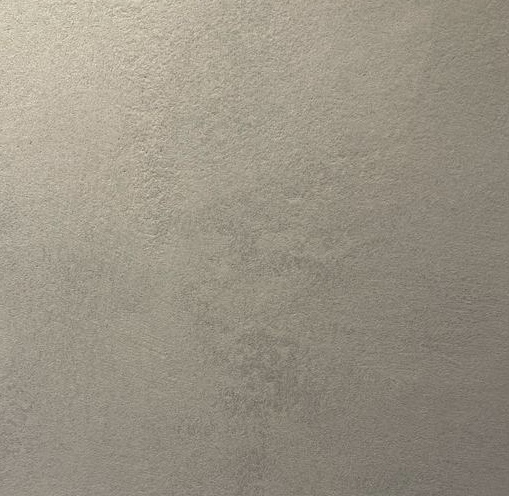

Microcement FINE

Finally, we have the ClaudiCemento Fine finish, characterised by its almost invisible grain size. This delicate and subtle option offers a beautifully cloudy effect with visible colour variations. What sets the ClaudiCemento Fine finish apart are the captivating burnishing marks, which add depth and texture to the microcement surface. Customers simply can’t resist the unique and sophisticated pattern it creates.